Understanding Spec Sheets: A Quick Guide

Spec sheets are vital documents in manufacturing, engineering, construction, and electronics. They offer detailed information about product features and technical specifications. These guides are crucial for stakeholders in product development and decision-making.

Spec sheets help make informed decisions and ensure quality. They’re useful for product managers, designers, purchasing agents, and customers. This guide will explore key aspects of spec sheets and their applications.

Key Takeaways

- Spec sheets provide detailed information about a product’s features, specifications, and technical details.

- They are essential for stakeholders involved in product development, manufacturing, and quality control.

- Spec sheets can help ensure clarity, quality assurance, product differentiation, and better procurement decisions.

- They can reflect a brand’s commitment to quality, innovation, and transparency.

- Spec sheets are used in a wide range of industries, including manufacturing, engineering, construction, and electronics.

What is a Spec Sheet?

A spec sheet provides detailed information about a product’s features and technical details. It’s a vital document for stakeholders in product development, manufacturing, and quality control. Spec sheets guide the entire product lifecycle.

These sheets are used in manufacturing, engineering, construction, and electronics industries. They explain the “what, how, and why” of product production and sales. This ensures consistency and accuracy throughout the process.

Project managers, designers, and quality teams use spec sheets to align their efforts. These documents outline product descriptions, dimensions, materials, and components. They also include specifications, manufacturing processes, and testing details.

“Spec sheets are essential for delivering the best products to customers. Nearly 50% of companies fail to do so due to not utilizing these critical documents.”

Spec sheets provide a central source of product information. This facilitates effective communication among stakeholders. It helps ensure the final product meets desired standards and customer expectations.

In conclusion, spec sheets are crucial tools for businesses. They streamline product development and manufacturing processes. This helps companies deliver high-quality products to their customers efficiently.

Importance of Using Spec Sheets

Product spec sheets are key to successful product development and management. They provide clarity, support quality assurance, and guide design processes. These documents help with sourcing and serve as crucial references throughout a product’s lifecycle.

Well-written spec sheets prevent misunderstandings and maintain consistent quality. They ensure the final product meets everyone’s expectations. Spec sheets coordinate teams and communicate specific requirements effectively.

Accurate spec sheets prevent budget overruns and missed deadlines. They also ensure project deliverables are in usable states. Clear spec sheets are essential to avoid confusion and ensure project alignment.

- Spec sheets typically include six basic categories of information: general information, proposed production schedule, bid specs, elements and materials list, deliverables list, and a notes and comments section.

- Thousands of new products are released every year, with a majority facing failure due to various reasons such as low consumer demand, poor marketing, and unexpected costs. A well-written product specification sheet is crucial for successfully launching a new product.

- Product spec sheets are essential for communicating product design details and ensuring regulatory compliance. Sales and marketing teams also benefit from these sheets to understand the product’s value and create effective promotions.

Organizations can streamline product development using spec sheets. This leads to better outcomes and increased customer satisfaction. Spec sheets serve as roadmaps, aligning with customer needs throughout a product’s lifecycle.

“A well-written and regularly updated spec sheet serves as a guideline for launching a successful product by reflecting changing customer demands and market conditions.”

Spec sheets ensure clarity and support quality assurance. They guide design processes and serve as crucial reference points. Comprehensive spec sheets help organizations succeed in today’s competitive product landscape.

Components of a Spec Sheet

A well-crafted spec sheet is a vital guide for product details. It provides key information about features, specs, and technical aspects. This document helps all teams understand the product clearly.

The components of a spec sheet typically include:

- Product name and information

- Product description

- Dimensions

- Materials and components

- Specifications and requirements

- Manufacturing processes

- Testing and validation details

- Safety and compliance information

- Product images and diagrams

- Additional relevant information

These spec sheet elements ensure clear communication of product details. They enable informed decisions and effective product management throughout its lifecycle.

“A well-crafted spec sheet is the foundation for successful product development and manufacturing.”

Spec sheet content may vary by industry and product type. However, including core components is crucial for a thorough product understanding.

Using these components of a spec sheet helps manufacturers communicate key info. It ensures all teams are aligned and can make smart choices throughout the product’s life.

Creating Effective spec sheets

Effective spec sheets are crucial for successful product development and launch. They clearly communicate product vision and requirements to all stakeholders. Organizations can create impactful spec sheets by following best practices and including essential elements.

Here are some tips for writing effective spec sheets:

- Define the Problem: Clearly state the problem your product solves. This helps focus on critical features and specifications.

- Conduct Thorough Research: Gather information about your target market, competitors, and industry standards. This research will guide your spec sheet’s content and structure.

- Write a Clear and Concise Summary: Provide a brief summary of key features and benefits. Use simple language that’s easy to understand.

- Include a Timeline and Budget: Outline development and delivery timeline, and associated budget. This sets realistic expectations and ensures successful project management.

- Select Relevant Specifications: Include important product specs like dimensions, materials, performance requirements, and compliance standards.

- Run User Tests: Conduct testing to check your spec sheet’s effectiveness. Gather feedback for ongoing improvements.

- Gather and Implement Feedback: Regularly collect stakeholder input and update your spec sheet. This keeps it relevant and accurate.

- Launch and Collect Post-Launch Feedback: After launch, gather customer feedback. Use it to refine your spec sheet for future versions.

Following these best practices for how to create a spec sheet leads to better product launches. It helps develop best practices for spec sheets that effectively communicate product vision and requirements.

| Spec Sheet Component | Description |

|---|---|

| Product Summary | A brief overview of the product’s key features and benefits. |

| Features and Requirements | A detailed list of the product’s features, functionalities, and technical requirements. |

| Development and Delivery Timeline | A timeline outlining the product’s development and delivery milestones. |

| Development and Delivery Budget | The estimated budget for the product’s development and delivery. |

| Risks and Challenges | A list of potential risks and challenges that may impact the product’s development and launch. |

These tips for writing spec sheets help create clear and customer-focused documents. They improve product development and launch efforts, increasing chances of success.

“Effective spec sheets are the foundation of successful product development and launch. By investing time and effort into creating a comprehensive and customer-focused spec sheet, organizations can better communicate their product vision and increase their chances of success.”

Best Practices for Spec Sheets

Effective spec sheets are vital for product development and manufacturing success. Clear specifications ensure alignment with suppliers and stakeholders. Here are some key guidelines to follow:

- Use clear and concise language: Avoid jargon or complex terms. Write in a straightforward, customer-friendly way.

- Treat spec sheets as living documents: Update them regularly to reflect changes in specs, processes, or standards.

- Maintain version control: Ensure everyone has access to the latest version. This prevents confusion and inconsistencies.

- Balance technical details and customer-friendly information: Provide comprehensive specs while making them easy for non-technical stakeholders to understand.

- Incorporate visuals: Include product images, diagrams, or illustrations. These enhance readability and understanding.

- Organize content effectively: Use clear headings, sections, and formatting. This makes your spec sheet easy to navigate.

Following these best practices for spec sheets creates informative and actionable documents. These support your product development goals effectively.

They also provide tips for writing effective spec sheets. Your guidelines for spec sheets will meet stakeholder needs.

“Clearly defining the specifications of products in a product specification sheet can assist in achieving better results throughout the production process and sourcing.”

Spec Sheets in Different Industries

Spec sheets are vital tools across various industries. In manufacturing, they guide design, development, and quality control processes. These documents ensure products meet the highest standards.

Spec sheets in manufacturing offer a complete overview of product features and materials. They enable smooth collaboration between designers, engineers, and production teams.

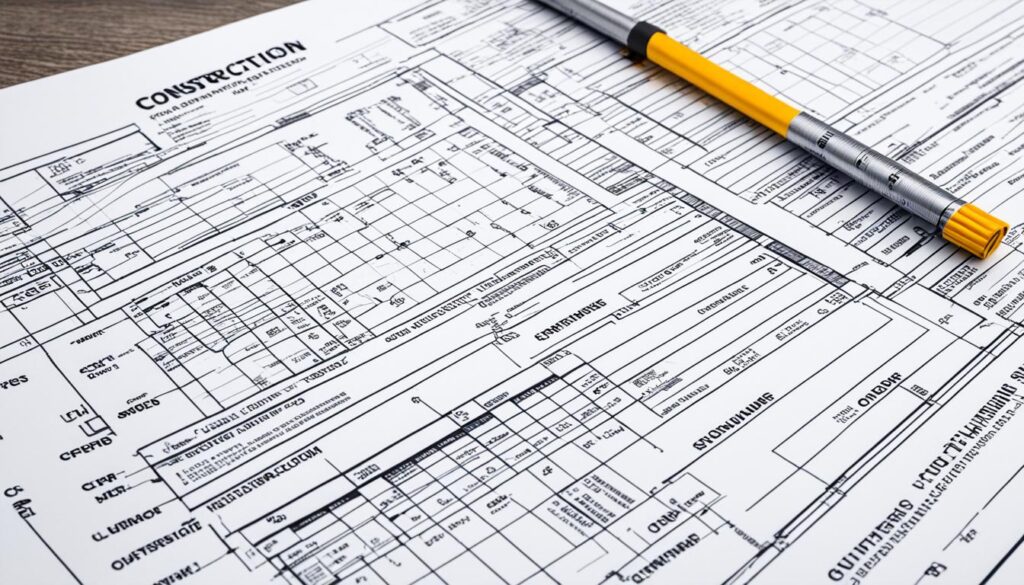

In construction and engineering, spec sheets play a crucial role. They ensure products and materials align with design standards and functional requirements. These documents help professionals make informed decisions about building components.

The electronics industry relies heavily on spec sheets for technical information. They detail product features, performance, and compliance with safety standards. These resources aid in development, production, and promotion of electronic devices.

| Industry | Spec Sheet Focus | Key Considerations |

|---|---|---|

| Manufacturing | Product design, development, and quality control | Materials, production methods, performance specifications |

| Construction | Adherence to design standards and functional requirements | Building codes, safety regulations, aesthetic integration |

| Electronics | Technical specifications, safety, and regulatory compliance | Features, performance, power consumption, certifications |

Spec sheets are the backbone of informed decision-making across industries. They streamline production and ensure high-quality products and services. These documents help meet the needs of customers and stakeholders.

Spec Sheets and Design Standards

Spec sheets are vital in interior design and construction. They ensure products align with design standards and project requirements. These documents provide details on dimensions, materials, and performance characteristics.

Spec sheets help verify if chosen items meet the design vision. They also ensure compliance with regulations and industry standards. This information is crucial for project success.

Importance of Spec Sheets in Interior Design and Construction

Designers and construction pros use spec sheets to make informed choices. These documents help select elements that match the desired look. They also ensure items meet functional and safety needs.

Spec sheets provide technical info for confident product selection. This helps teams adhere to design standards and construction specifications. It’s a key tool for project success.

| Industry | Importance of Spec Sheets |

|---|---|

| Interior Design | Spec sheets help interior designers evaluate the suitability of furniture, finishes, and fixtures for a space, ensuring they meet aesthetic and performance criteria. |

| Construction | In construction projects, spec sheets are crucial for verifying that building materials, systems, and components comply with the project’s design standards and construction specifications. |

Spec sheets guide professionals in making smart choices. This leads to visually appealing projects that work well. It also ensures safety and performance standards are met.

“Spec sheets are an essential tool for ensuring that the products and materials selected for a project align with the desired design vision and meet the necessary performance criteria.”

Spec sheets are key in design and construction. They help pros choose products that fit design and function needs. This results in successful, high-quality projects.

Formatting and Presenting Spec Sheets

A well-formatted spec sheet is key to effective communication. It clearly conveys product details to stakeholders. An organized, visually appealing design is crucial for this purpose.

Here are some best practices for formatting and presenting spec sheets:

- Layout and Structure – Use a clean layout with clear sections and headings. This helps readers find information quickly.

- Visual Elements – Add product images, diagrams, and charts to support the text. These visual aids make the spec sheet more engaging.

- Branding and Design – Align the spec sheet’s design with your company’s visual identity. This builds credibility and reinforces the product’s image.

- Readability – Choose appropriate font size, style, and spacing. Avoid overcrowding and allow for white space.

- Consistency – Use a consistent format across all spec sheets. This creates a cohesive brand experience for your audience.

Formatting spec sheets with a focus on visual appeal enhances communication. This approach helps optimize spec sheet design for showcasing product features effectively.

“A well-designed spec sheet can make all the difference in how your product is perceived and understood by your target audience.”

Spec Sheets for Product Lifecycle Management

Spec sheets are crucial in product lifecycle management. They serve as a reference point throughout product development and production. These sheets ensure consistency, quality, and continuous improvement.

Spec sheets act as a central repository of product data. They help stakeholders make informed decisions and track progress. This approach ensures products meet customer needs and business goals.

- Specification sheets document technical requirements, features, and performance details, providing a clear roadmap for design, development, and manufacturing.

- During production, spec sheets ensure that the manufactured product adheres to the defined standards, enabling consistent quality control and compliance.

- Ongoing maintenance and updates are facilitated by the comprehensive information in the spec sheet, allowing for seamless product enhancements and revisions.

- Spec sheets serve as a valuable reference for sales and marketing teams, empowering them to provide customers with detailed product information and personalized recommendations.

Spec sheets throughout the product lifecycle boost organizational efficiency. They improve collaboration and product quality. This helps meet customers’ changing needs effectively.

| Stage | Role of Spec Sheets |

|---|---|

| Design and Development | Documenting technical requirements, features, and performance details |

| Manufacturing | Ensuring consistent quality control and compliance |

| Maintenance and Updates | Facilitating seamless product enhancements and revisions |

| Sales and Marketing | Empowering sales teams with detailed product information and personalized recommendations |

“Developing a clear product specification provides a blueprint for design, development, testing, and product launch.”

Using spec sheets throughout the product lifecycle offers numerous benefits. They streamline processes and enhance teamwork. As a result, organizations can deliver top-notch products that surpass customer expectations.

Conclusion

Spec sheets are vital documents that detail a product’s features and technical attributes. They serve as key resources for stakeholders in product development and quality control. Well-crafted spec sheets ensure clarity, support quality assurance, and guide the design process.

These documents streamline sourcing and procurement for organizations. They also maintain a reference point throughout a product’s lifecycle. Spec sheets are used across various industries, each with unique requirements.

In interior design and construction, spec sheets ensure products meet design standards. They help materials adhere to aesthetic and functional requirements. Effective spec sheets enhance operational efficiency and minimize risks.

Organizations should prioritize developing comprehensive and user-friendly spec sheets. Following best practices in spec sheet creation streamlines product development. It improves quality control and drives success in respective markets.

FAQ

What is a spec sheet?

A spec sheet provides detailed info about a product’s features and specs. It’s a comprehensive guide for stakeholders in product development, manufacturing, and quality control. This document is also known as a specification sheet.

Why are spec sheets important?

Spec sheets are vital in product development and management. They offer clarity and support quality assurance. These documents guide design processes, help with sourcing, and serve as a reference throughout a product’s lifecycle.

What are the key components of a spec sheet?

A good spec sheet includes product name, description, and dimensions. It also covers materials, specifications, and manufacturing processes. Testing details, safety info, and product images are important too.

How do I create an effective spec sheet?

Start by defining the problem and doing thorough research. Write a clear summary and include a timeline and budget. Choose the right product specs to include.

Run user tests and gather feedback. Finally, launch the product with confidence.

What are the best practices for spec sheets?

Use clear language and keep the document customer-focused. Treat it as a living document that’s updated regularly. Ensure everyone has access to the latest version.

Strike a balance between technical details and customer-friendly info. This approach makes spec sheets more useful and accessible.

How are spec sheets used in different industries?

Spec sheets guide design and quality control in manufacturing. In construction, they ensure products meet design standards. For electronics, they provide detailed tech info about features and safety compliance.

How do spec sheets relate to design standards?

In interior design and construction, spec sheets ensure products meet design standards. They help verify that chosen items align with the overall vision. Spec sheets also confirm compliance with relevant regulations.

How should spec sheets be formatted and presented?

Use a clear layout with distinct sections and headings. Include product images or diagrams to enhance understanding. The design should align with the company’s image and values.

A well-formatted spec sheet establishes credibility and reinforces the product’s identity. It makes information easy to find and understand.

How do spec sheets support product lifecycle management?

Spec sheets are crucial throughout the product development process. They provide a reference point from initial design to ongoing maintenance. This detailed info ensures consistency, quality, and continuous improvement.

As a central data repository, spec sheets help stakeholders make informed decisions. They also allow teams to track progress and optimize products over time.